Z8 Teardown Gives You a Look Inside Nikon’s Latest

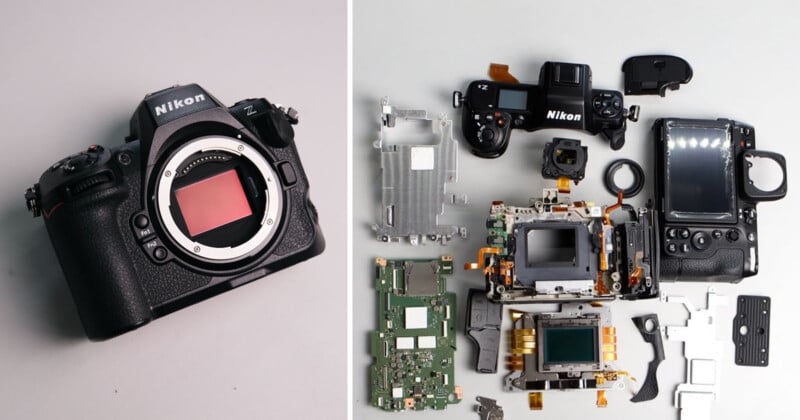

Kolari specializes in infrared and ultraviolet photography camera conversions. The company also makes filters and even built a camera out of a potato. As part of its camera conversion work, Kolari often shares teardowns of new cameras, like a detailed teardown of the Sony a1. The latest camera to hit the operating table is the Nikon Z8 full-frame mirrorless camera.

In many ways, the new Z8 is a lot like the Z9 that Nikon released at the end of 2021 and which Kolari did a teardown of last summer. That flagship camera features a stacked 45.7-megapixel image sensor that lacks a mechanical shutter of any kind. Where the Z8 and Z9 differ most dramatically is the overall look and design of the camera around that sensor.

The Z9 sports a pro-style, dual-gripped body that is very robust — and quite large and heavy. The Nikon Z8, on the other hand, looks more like a slightly shrunken Nikon D850 DSLR. The Z8 is bigger than the Z6 II and Z7 II, which share an identical camera body, but quite a bit smaller than the Z9, thanks to the omission of an integrated vertical grip.

To disassemble the Z8, the first step is to remove the camera’s baseplate and the seven included screws. Removing screws is a big part of any camera teardown, but Kolari’s technician notes that the Z8 has so many screws that it was challenging to keep track of them all. There are five screws under the battery compartment door and five screws beneath the dust cap that covers the Z8’s side ports, including a full-size HDMI port, a pair of USB-C ports, and separate mic and headphone jacks.

There are more screws around the EVF housing, inside the card slot, along the camera’s right side, and beneath the eyecup cover.

Once all the screws and the tripod plate have been removed, the technician carefully pries the rear panel from the rest of the Z8’s body. After disconnecting the ribbon cables that connect the rear panel to the camera’s processor, it is time to disconnect the rest of the cables connected to the circuit board. There are nearly as many cables as there are screws.

While nothing about the Z8’s design stands out, it is incredible to see how many different components are jampacked inside the camera body. It is immediately evident how much careful planning and engineering goes into every part of any camera, especially a high-end one like the Z8.

Although Nikon has struggled with a bit of quality control surrounding the Z8 since its release in May, there is no doubt that it is a thoughtfully engineered camera.

Kolari’s blog post detailing the Nikon Z8 teardown has dozens of detailed photos showing every part of the disassembly, including a closer look at the camera’s sensor. Kolari notes that the Z8 uses springs for focus calibration. The three springs are carefully calibrated to ensure the sensor is perfectly parallel to the focal plane.

“We consider the Nikon Z8 camera a mid-difficulty camera to tear down. According to our camera tech, there were so many screws to keep track of. This usually makes for a difficult process of tearing down and putting back together,” Kolari concludes.

More information about Kolari’s camera conversion services and other products is available on its website.