Fujifilm X-H2 Teardown Shows Clever Thermal Design and Robust IBIS

![]()

Sven Lamprecht of IRreCams specializes in infrared and astrophotography camera conversions. As part of his work, he recently performed a full spectrum conversion on his Fujifilm X-H2 camera, and detailed the entire teardown on his website.

The Fujifilm X-H2 features Fujifilm’s high-resolution X-Trans CMOS 5 HR sensor, an industry-leading APS-C sensor, and the first of its kind to hit 40 megapixels. As a flagship mirrorless camera built for professionals — including hybrid shooters thanks to 8K RAW video capabilities — the X-H2 is built with thermal performance in mind. During sustained use, the camera must deal with heat. Part of Lamprecht’s teardown is seeing the X-H2’s clever thermal design.

Opening the X-H2 is surprisingly simple. There aren’t many screws on the casing, and they’re in the usual places for a Fujifilm camera. There are some screws hidden around the body beneath the leatherette grip, but cracking open the body is a straightforward affair.

Once the screws are removed, Lamprecht can remove the camera’s bottom plate, exposing a large aluminum plate. “This surface is connected to the bottom via a heat conduction pad to dissipate heat from the inside,” Lamprecht explains.

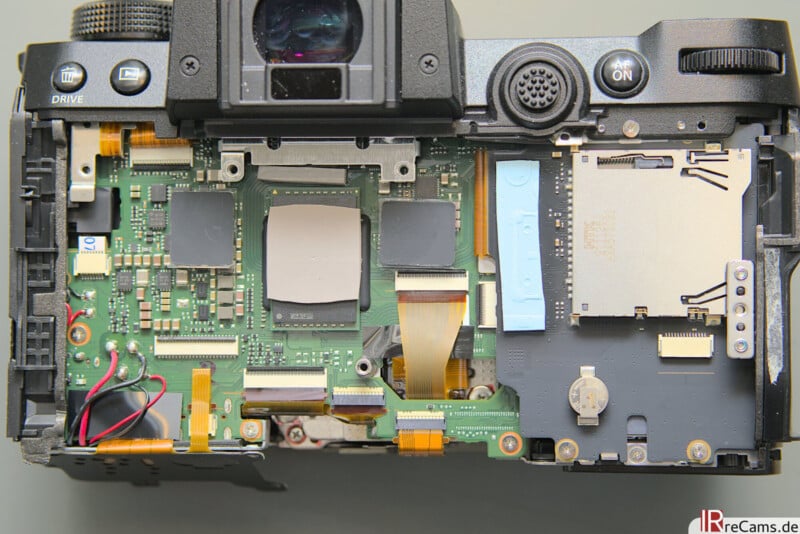

Looking up through the bottom of the X-H2, there’s not much to see behind the camera’s display. There are ports for the camera’s optional FAN-001 attachment, which is also compatible with the new X-S20 camera and the other X-H2 model, the high-speed X-H2S. After removing some additional screws inside the camera, the back part of the X-H2 and its display can be removed, revealing the camera’s primary board.

On the backside of the camera’s rear plate, there’s another large piece of aluminum for heat dissipation.

“The heat from various components of the motherboard, especially the heat from the processor, is conducted directly into this plate and distributed via heat conduction pads. This heat can then be dissipated to the environment via the back case behind the display (keyword ‘FAN-001’) and the bottom,” writes Lamprecht.

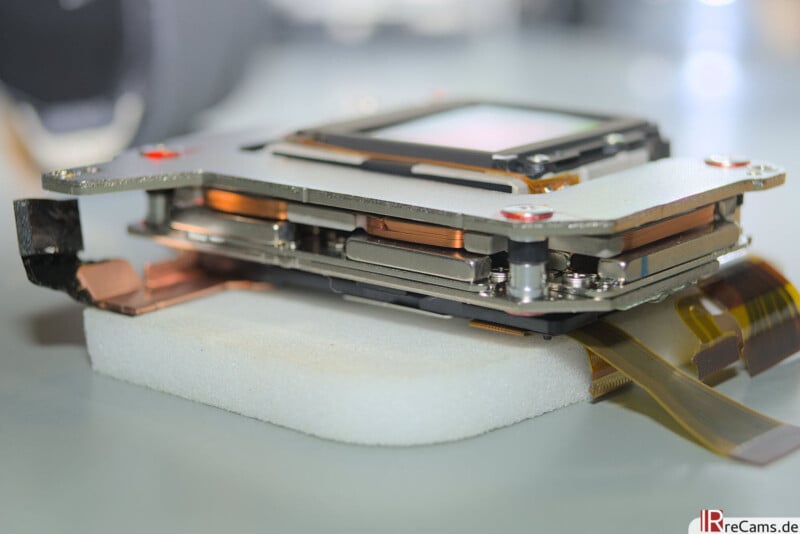

While aluminum is known for its thermal conductivity, it’s less effective than copper. It’s unsurprising, then, that there’s copper in the X-H2 as well. Around the image sensor, there’s a copper contact surface and another heat pad. The heat from the image sensor is transferred to the copper, then to the heat pad, and then moved upward into the upper case of the X-H2’s OLED viewfinder.

Lamprecht also found that each of the X-H2’s card slots, one SD and one CFexpress, include their own circuit boards. After removing these circuit boards from the camera, Lamprecht can begin removing the camera’s primary board. This process includes removing screws and performing some careful unsoldering work.

“A closer look at the removed mainboard of the X-H2 reveals countless SMD components, both on the top and the bottom. With the amount of features packed into such a small camera, this is hardly surprising. The new X-Processor 5 is placed in the middle of the board, and it’s slightly higher than the rest of the board. It seems to be installed on a small socket, almost floating above the other components. Whether this was designed because of the heat development, or has entirely different reasons, can only be speculated. In any case, the processor is covered with a heat conduction pad and thus establishes the already mentioned connection to the camera’s back plate,” he says of the camera’s board.

After finding more aluminum inside the camera, Lamprecht removed the X-H2’s newly designed five-axis in-body image stabilization (IBIS) system. It’s a robust, large component that takes up significant space inside the camera body.

Nearby, the camera’s shutter mechanism is notable. Like the X-H1, the X-H2’s “entire shutter mechanism is supported by small springs all around and has no direct contact with the body.” Lamprecht says this explains why the X-H2 has a relatively quiet shutter sound.

Looking at the image sensor, the star of the show, and the primary reason that Lamprecht took apart his X-H2, it’s a beautiful chip. Aided by the new IBIS system, which can precisely move the sensor with pixel precision, the X-H2 can capture 160-megapixel composite images, which combine 20 individual photos.

The sensor also generates quite a bit of heat. “With all those pixels, it’s obvious that the sensor must generate quite a bit of heat. This heat is tapped directly on the back of the sensor via a delicate heat sink and conducted to a copper plate on the stainless steel chassis. We had already seen at the beginning that the copper sheet makes contact with the upper part of the housing. A portion of the heat can therefore be conducted to the outside quite efficiently, I haven’t seen such a design from any other manufacturer so far,” explains Lamprecht.

With the sensor exposed, Lamprecht can replace the IR-cut filter in front of the image sensor with a 280-nanometer full spectrum filter.

“As with virtually all modern Fuji cameras, the filter stack in front of the sensor consists of 2 glasses. The top glass has a piezoelectric element responsible for automatic dust cleaning. The actual UV/IR blocking filter (Hotmirror) is installed directly below it. As with the X-H1, X-T3, and X-T4, this blocking filter is unfortunately so unfavorably glued into the small plastic frame that the complete filter stack has to be replaced. This means that the dust cleaning function of the camera is lost with this model,” he explains.

After converting his camera, Lamprecht’s X-H2 can capture images from ultraviolet to the infrared range, estimated to be about 340nm to 1,200nm. The visible light spectrum is from around 380nm to 700nm, by the way.

After reinstalling the converted sensor, it’s time for Lamprecht to put everything back together and take some infrared photos.

“The Fujifilm X-H2 is a complex camera that boasts remarkable specs and delivers great image quality. The camera’s construction and design are solid, uncompromising, and optimized for dissipating heat. Accordingly, the camera can shoot for a very long time with fast frame rates or create video in 8K. The 40 MP resolution is a welcome update to the existing sensors and also delivers more details in infrared than the predecessors,” Lamprecht concludes, giving the X-H2 his approval.

The Fujifilm X-H2 and X-H2S are available from IRreCams with infrared, full spectrum, or astro modifications. Many more images of the X-H2 camera during teardown and additional post-conversion sample images are available on the IRreCams website.

Image credits: Sven Lamprecht / IRreCam