Made in Japan: How (and Why) Sigma Does Things Differently

When Sigma announced its new cinema lens series earlier this year, that may have been the first time that some heard the word “Aizu.” Aizu, the shortened form of Aizuwakamatsu, refers to a region in Fukushima, in northern Honshu, Japan, where Sigma is based. This region and its people are so important to the core of what makes Sigma special that it only makes sense to name a lens series after it.

The Aizu basin is a secluded area surrounded on all sides by majestic mountains, with numerous freshwater springs providing crystal clear water throughout the valley. It is here that you will find the hardworking people of Aizu who maintain a strong regional identity to this day.

The Sigma Lens Factory was founded in Aizu, where access to pristine water was essential for polishing lenses. The people of Aizu are fiercely proud of the traditions that have been passed down since the time of the samurai. There is a spirit of independence, of dedication to hard work, craftsmanship, and loyalty. And it is this same spirit that the Sigma company holds true at its core.

![]()

While many, if not all, other Japanese camera optics manufacturers have shifted production outside of Japan at least in some capacity (if not entirely), Sigma remains fully committed to manufacturing fully in Aizu. PetaPixel had visited the factory previously, but we returned to take a closer look at just what makes Sigma capable of not only producing some of the finest optics photographers can ask for, but also doing so affordably while continuing to be a major employer of the region. There are many who would argue that the combination of quality, affordability, and local production simply cannot mix. So, why can Sigma do it, and what makes its method special?

![]()

When describing lens manufacturing, it’s pretty easy to skip straight over to glass and metal, but there are other important components that need to be made as well. For example, Sigma has an in-house Electrical Component Mounting Division, where machines mount electrical components onto the circuit boards for both cameras. and lenses.

Sigma has been manufacturing its own circuit boards for about 40 years (the company first started this practice back in 1985). Sigma has multiple machines that can mount these electrical components onto circuit board with high-speed and ultra high-precision. Once these pieces have been assempled, a quality control team checks to ensure each PCB is functioning correctly before they move on to be used in Sigma cameras and lenses.

![]()

Sigma not only makes a vast majority of its own metal parts for its lenses and camera bodies, it also manufactures its own metal and plastic tools — including molds, dies, and jigs — that are also required to make each part of a Sigma product. These sections of the factory are the Metal Processing Division and the Tool & Die Manufacturing Division. This level of vertical integration is key to Sigma’s success.

Having these particular divisions in-house is a step many manufacturers may choose to skip, as it requires a huge investment in lathes, machining centers, multi-tasking CNC machines, and specialized machines for cutting screw, gears, and other small, specialized parts. These pieces need to be very precise — often down to a micron scale — and Sigma is able to do this in-house. Sigma’s factory can process parts as small as 1mm in diameter.

![]()

Sigma not only makes the small parts that come together to form its cameras and lenses, it makes the tools that make those small parts.

Such capability requires a large investment up-front, but with these machines, Sigma is able to be more flexible and adaptable in its manufacturing. If a particular part is needed for a new design, odds are high that Sigma can create that part itself rather than have to work with another factory which would take longer and cost more. In this way, Sigma can operate on its own schedule.

This section of the factory is also in charge of processing the Sigma BF camera bodies out of a single, thick aluminum ingot using the latest in five-axis machining technology as well as automated loading and unloading machines to aid in keeping up with demand for this highly-sought after product. Sigma has a team of robots that are responsible for loading and unloading these CNC machines and, yes, they sing while they work.

![]()

![]()

Just as was the case in the electrical components section, these two divisions have multiple quality control checks using a variety of precise gauges as well as 3D measurement machines before the parts move on to be coated or further processed.

While Sigma’s factory is full of a machines and uses quite a bit of automation, there are still steps it prefers to do by hand. For example, its Color Inlay team (which is part of its Plasticity Division) is where the recessed lettering is applied by hand by skilled inlay technicians. While it’s not used in all Sigma products, this inlay design helps protect lettering from being worn away over time. These inlays are painted individually — proof of Sigma’s hand-crafted quality claims.

![]()

Again, meticulous quality control checks are carried out in this division, this time at each station to ensure the lettering is applied precisely.

By this point, it should not come as a surprise that Sigma is especially proud of its glass work. While Sigma designs and manufactures cameras and other photographic accessories today, its start was in optics, giving it over 60 years of lens processing expertise in our pursuit of mastering the craft. In Sigma’s factory, glass elements are individually ground and precision polished, as thinly as hundredths of a millimeter, by hundreds of machines and technicians producing tens of thousands of lens elements per day.

![]()

![]()

Of course, there is no lack of quality checks in this division either, with precision curvature measurement ensuring that each lens element is in line with its rigorous specifications.

After receiving final precision polishing and passing internal quality control tests, the lens elements receive one or two of Sigma’s specialized anti-reflective coating processes: Super Multi-layer coating and/or the Nano Porous Coating, which are applied to reduce flare and ghosting as well as to give its lenses clear image quality.

![]()

![]()

![]()

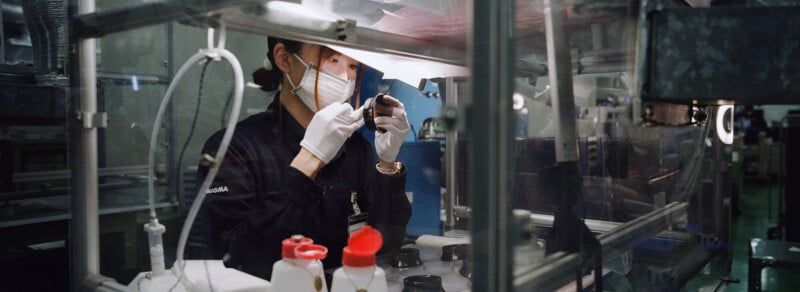

Before being carefully loaded and sent to the coating machines, every single lens element is inspected to ensure it is free of dust or other lens imperfections which could compromise the coating effectiveness.

Another proof of the hand-craftsmanship used in Sigma lenses is the use of black coating — integral in minimizing ghosting — which is applied by hand to the outer diameter of lens elements.

![]()

When it was mentioned how closely tied Sigma’s process is to the Aizu region, that also includes this hand painting process. The method by which Sigma applies this coating harkens back to Aizu’s history of fine lacquerware production, which is still performed in the region today. Those techniques have modern applications, as this is an extremely delicate process and as a result, it is extremely difficult to automate it. So, Sigma continues to foster that human element. This application, in particular, requires a great deal of skill and experience to master.

And so it’s in these camera bodies and optics all of that hard work, determination, expertise, and craftsmanship culminate. Sigma is able to make these beautiful, high-performance products by controlling every stage of production — with multiple quality control checks within each — from start to finish.

That is what makes Sigma unique.

![]()

Years ago, Sigma once said that it had aspirations of becoming as world renowned for its cameras and lenses as someone like Zeiss — a premium optics maker. Looking at where Sigma is now, it’s hard not to argue that it has achieved that goal. The company makes its own cameras and lenses, designing truly unique optical arrangements that aren’t just copies of popular formulas.

![]()

Hopefully, this close-up look at Sigma’s manufacturing in Aizu, Japan provides some context as to why the company is able to do things so differently and how it is able to find a balance between quality and affordability that remains unique in the market today.

Unless otherwise noted, images captured with Sigma Aizu Primes.

Full disclosure: Sigma provided access to its facility with the stipulation that it could review images and video footage ahead of publication to assure correct descriptions of topics and visuals as well as to protect against the accidental publication of trade secrets.