This Rasperry Pi Instant Camera Prints Photos on Sticker Paper

Raspberry Pi computers are a boon for tinkerers inclined to design one-of-a-kind cameras. And now one Redditor has made a Raspberry Pi Zero-based instant camera.

Known online as Spacerower, the maker and developer has engineered a DIY handheld camera that not only captures images but instantly prints them out on sticker paper.

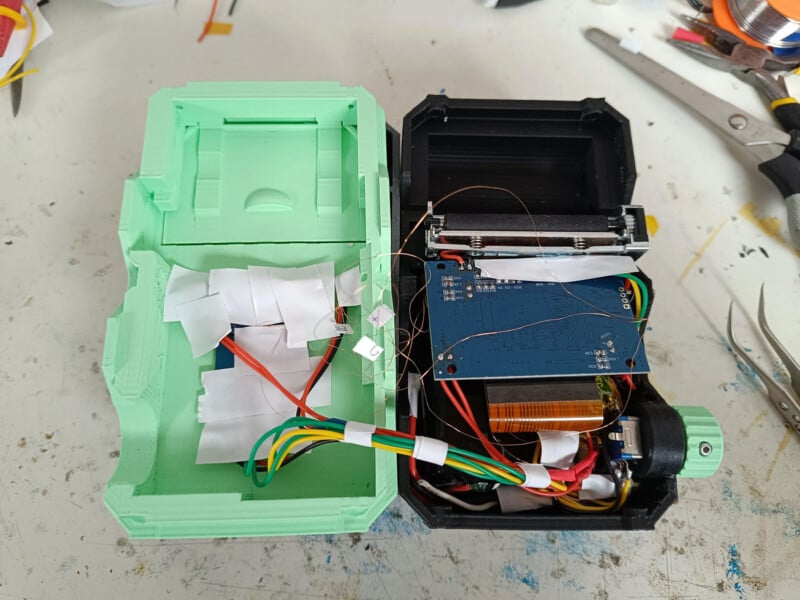

Built from scratch, the device uses a Raspberry Pi Zero as its brain, a Raspberry Pi camera module for capturing moments, and an Em5820 thermal printer to produce photos on the spot. Spacerower’s creation is a blend of retro charm and modern tech, complete with a 240x240px LCD screen for previewing shots.

“This is a project I’ve been working on for some time now,” writes Spacerower. “It contains a Pi Zero, a thermal printer that can print stickers, a Pi camera, a 1200mAh 2s lithium-ion battery, and some power circuits.”

To take a photo on the device, a quick press of the green button will snap an image. If you turn the green button knob, that will adjust the brightness of the image which can be seen on the tiny LCD screen. If you want to print a photo, then long press the shutter button and a peelable photo that can be stuck anywhere will appear.

The housing, designed and 3D-printed by Spacerower, is a custom fit for the project’s components. The case, printed in Polylactic Acid (PLA), can be replicated with any filament type. A clever mechanism even allows users to twist a black ring around the lens to shield it from scratches.

Under the hood, Spacerower’s creation relies on a custom Python script utilizing the picamera2 library for image capture and python-escpos to manage printing. Spacerower made a Printables page for the project in which they list all of the parts used.

Despite multiple requests for a full tutorial, Spacerower says it was too difficult a build to make one but they have done their best in the Reddit thread to answer questions if you want to give it a go yourself.